When it comes to safeguarding your gear against the elements and ensuring its longevity, coatings play a pivotal role. Understanding the significance of coatings in gear protection sets the stage for exploring one of the most advanced options available: Cerakote. Join us in learning the advantages of Cerakote below.

Setting the Stage: Understanding the Role of Coatings in Gear Protection

Before delving into the specifics of Cerakote coatings, it’s essential to grasp the fundamental role that coatings play in protecting gear. Whether it’s firearms, automotive parts, outdoor equipment, or industrial tools, coatings act as a shield, guarding against corrosion, wear and tear, and environmental damage. They prolong the lifespan of gear and maintain its aesthetic appeal despite challenging conditions.

What is Cerakote?

Unveiling Cerakote: A Brief Overview

Cerakote is a ceramic-based finish that offers exceptional durability and versatility. Developed by NIC Industries, it was initially formulated for firearms, but its applications have since expanded across various industries. Unlike traditional coatings, Cerakote bonds on a molecular level with the substrate, creating a tough, protective layer that enhances both performance and aesthetics.

The Evolution of Cerakote Technology

Since its introduction, Cerakote technology has undergone significant advancements. From improvements in application techniques to the development of specialized formulations for specific applications, such as automotive and outdoor gear, Cerakote continues to evolve to meet the ever-changing demands of different industries. This ongoing innovation ensures that the advantages of Cerakote remains at the forefront of protective coating solutions.

Advantages of Cerakote Coatings

Durability Redefined: Resisting Wear and Tear

One of the most prominent advantages of Cerakote coatings is their unparalleled durability. The ceramic-based formula forms a tough, abrasion-resistant barrier that withstands the rigors of daily use. Whether subjected to rough handling or exposure to harsh environments, gear coated with Cerakote remains resilient, maintaining its integrity over extended periods.

Versatility Unleashed: Adaptable to Various Surfaces

Another of the advantages of Cerakote coatings is that they exhibit exceptional versatility, adhering to a wide range of substrates, including metals, plastics, and composites. This adaptability makes Cerakote suitable for diverse applications, from firearms and automotive components to sporting equipment and industrial tools. Regardless of the material, Cerakote provides reliable protection and enhances the performance of the coated surface.

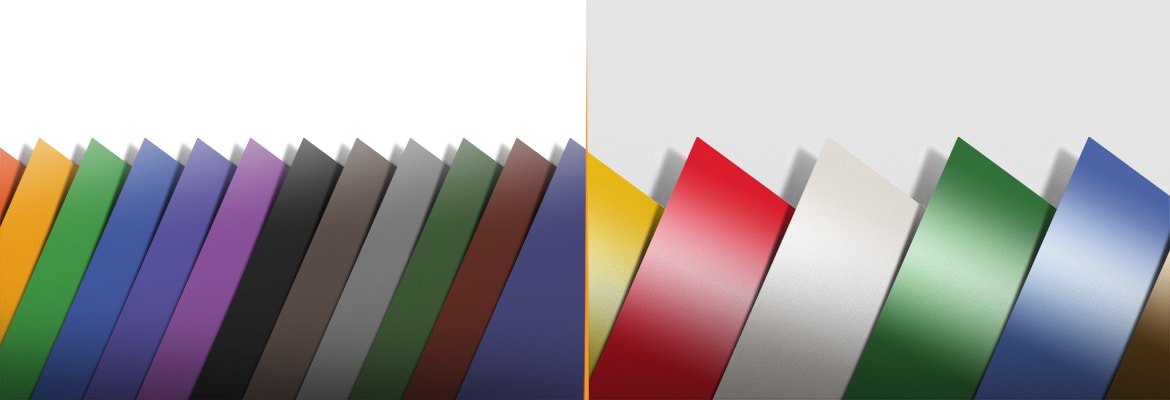

Aesthetic Appeal: Enhancing the Look of Your Gear

In addition to its protective qualities, another of the advantages of Cerakote is its many offerings of aesthetic benefits, allowing gear to stand out with vibrant colors and finishes. Whether you prefer a sleek matte black or a custom camouflage pattern, Cerakote provides endless possibilities for personalization. Its ability to maintain color fastness and resist fading ensures that your gear looks as good as it performs.

Corrosion Protection: Shielding Against the Elements

One of the primary functions of Cerakote coatings is to protect gear from corrosion caused by exposure to moisture, salt, and other corrosive elements. By forming a barrier between the substrate and the environment, Cerakote prevents oxidation and rust, prolonging the lifespan of metal components and ensuring reliable performance in adverse conditions.

Temperature Regulation: Heat Resistance and Thermal Control

Cerakote coatings are engineered to withstand high temperatures, making them ideal for applications where heat resistance is essential. Whether it’s firearm barrels subjected to rapid firing or automotive exhaust systems exposed to intense heat, Cerakote maintains its integrity, providing thermal insulation and preventing heat-related damage.

Chemical Resistance: Safeguarding Against Harsh Substances

Gear coated with Cerakote is resistant to a wide range of chemicals, including solvents, oils, and cleaning agents. This chemical resistance not only protects the substrate from corrosion but also simplifies maintenance, as the coating can be easily cleaned without fear of damage or degradation.

UV Resistance: Preventing Fading and Discoloration

Exposure to ultraviolet (UV) radiation can cause colors to fade and surfaces to degrade over time. Cerakote coatings incorporate UV stabilizers that mitigate the effects of UV exposure, preserving the integrity of the coating and preventing unsightly discoloration. This UV resistance ensures that gear retains its vibrant appearance even when exposed to sunlight for extended periods.

Thickness Options: Tailoring Coating Thickness to Needs

Cerakote coatings are available in various thickness options, allowing users to customize the level of protection based on their specific requirements. Whether you need a thin, lightweight coating for precision firearms or a thicker, more robust coating for industrial equipment, Cerakote offers flexibility without compromising performance.

Applications of Cerakote

Firearms: Enhancing Performance and Aesthetics

When it comes to firearms, enhancing performance and aesthetics is paramount. Cerakote coatings offer a winning combination of durability and customization options, allowing firearm enthusiasts to personalize their weapons while improving functionality. From reducing friction and wear on moving parts to providing a wide array of color choices and patterns, the advantages of Cerakote coatings elevates firearms to new levels of performance and visual appeal. Whether on the range or in the field, Cerakote-coated firearms stand out for their enhanced durability and striking appearance. Check out our work here.

Automotive: Protecting and Personalizing Vehicles

When it comes to automotive applications, Cerakote coatings offer a dual advantage of protecting and personalizing vehicles. From engine components to wheels and trim, Cerakote provides a durable barrier against corrosion and abrasion, extending the lifespan of automotive parts. Moreover, with a wide range of color options and finishes available, Cerakote allows car enthusiasts to add a unique touch to their vehicles, turning heads on the road while ensuring long-lasting protection against the elements.

Outdoor Gear: Weatherproofing for Adventure

When it comes to outdoor adventures, having gear that can withstand the elements is essential. That’s where the advantages of Cerakote coatings come in. Weatherproofing for adventure is what Cerakote does best. Whether you’re hiking through rugged terrain or braving the elements on a camping trip, Cerakote-coated gear offers unparalleled protection against corrosion and abrasion. From knives and camping equipment to optics and firearms, Cerakote ensures that your gear remains reliable and functional, no matter what Mother Nature throws your way.

Sporting Equipment: Durability for Peak Performance

When it comes to sporting equipment, durability is key to achieving peak performance. Cerakote coatings offer a winning solution, providing a robust protective layer that withstands the rigors of intense activity. From golf clubs and bicycles to fishing rods and athletic gear, Cerakote ensures that your equipment remains in top condition, even during the most demanding competitions. With Cerakote, athletes can focus on their game without worrying about equipment failure or deterioration.

Industrial Tools: Extending Lifespan and Functionality

When it comes to industrial tools, extending lifespan and functionality is paramount. Cerakote coatings provide a durable protective layer that enhances the performance and longevity of industrial equipment. From cutting tools and machinery components to hydraulic cylinders and manufacturing fixtures, the advantages of Cerakote is that that tools can withstand the harsh conditions of industrial environments. With Cerakote, businesses can minimize downtime and maximize productivity by optimizing the performance of their equipment.

Cerakote Process Explained

Surface Preparation: Ensuring Proper Adhesion

Surface preparation is a critical step in the Cerakote coating process, ensuring proper adhesion and optimal performance. Before applying the coating, the substrate must be thoroughly cleaned and prepped to remove any contaminants or impurities that could interfere with adhesion. This typically involves sandblasting, chemical etching, or other methods to create a clean, rough surface for the coating to bond to. By prioritizing surface preparation, users can ensure that their Cerakote coatings adhere securely, resulting in durable and long-lasting finishes.

Application Techniques: Spraying for Even Coverage

Application techniques play a crucial role in achieving high-quality Cerakote finishes, with spraying being the preferred method for ensuring even coverage. Utilizing specialized spray equipment and techniques, applicators can achieve uniform distribution of the coating across the substrate, resulting in a smooth and consistent finish. By controlling factors such as spray pressure, distance, and angle, professionals can optimize the application process to achieve the desired thickness and appearance for each project.

Curing Process: Solidifying the Coating for Maximum Effectiveness

The curing process is the final step in the Cerakote coating application, where the coating is subjected to controlled heat to solidify and achieve maximum effectiveness. This process ensures that the coating fully bonds to the substrate, enhancing its durability and performance. Proper curing is essential for achieving long-lasting results.

Choosing the Right Cerakote

Considering Your Gear’s Use and Environment

Another of the advantages of Cerakote is the multiple series of products that Cerakote offers for different applications. When selecting the appropriate Cerakote formulation for your gear, it’s essential to consider factors such as the gear’s intended use and the environment it will be exposed to. Assessing these variables helps determine the optimal coating properties, ensuring that your gear receives the protection it needs to perform admirably in its specific context.

Consulting with Professionals: Expert Guidance

When consulting with professionals about Cerakote coatings, you’re tapping into a wealth of expertise that can make all the difference in your coating decisions. Navigating the myriad of Cerakote options can be overwhelming, which is why consulting with professionals is crucial. These experts possess in-depth knowledge of Cerakote formulations, application techniques, and industry trends, allowing them to provide tailored recommendations based on your specific needs and preferences.

By seeking expert guidance, you gain access to insights that can help you make informed choices about Cerakote coatings for your gear. Whether you’re a firearms enthusiast looking to optimize performance or an automotive aficionado aiming to personalize your vehicle, professionals can offer invaluable advice to ensure that you achieve the desired results.

In essence, consulting with professionals provides a strategic advantage in harnessing the full potential of Cerakote coatings for your gear. By leveraging their knowledge and insights, you can make confident decisions that enhance the durability, performance, and aesthetics of your coated surfaces.

Customization Options: Colors and Designs

When it comes to customization options for Cerakote coatings, the possibilities are virtually endless. With a wide range of colors and designs available, you can personalize your gear to reflect your unique style and preferences. Whether you prefer bold, vibrant hues or subtle, understated patterns, Cerakote offers customization options to suit every taste. The advantages of Cerakote are clear. Don’t skimp on style.

Caring for Cerakote Gear

Cleaning Tips: Maintaining the Coating’s Integrity

Cleaning tips are essential for preserving the integrity of Cerakote coatings. To maintain the coating’s durability and appearance, it’s crucial to use gentle cleaning methods and avoid abrasive materials that could scratch or damage the surface. Regular cleaning with mild soap and water helps remove dirt and debris without compromising the coating’s protective properties.

Long-Term Maintenance: Preserving the Coating’s Benefits

To ensure that Cerakote-coated gear continues to provide optimal protection and performance over the long term, it’s important to implement a comprehensive maintenance routine. This includes periodic inspections to identify any signs of wear or damage, as well as proactive measures to address potential issues before they escalate.

Comparing Cerakote to Other Coatings

Cerakote vs. Anodizing: Strengths and Weaknesses

Anodizing is a common coating method used to enhance the corrosion resistance and durability of metal surfaces, particularly aluminum. While anodizing provides a hard, protective layer, it lacks the versatility and customization options offered by Cerakote. Additionally, advantages of Cerakote coatings offer superior scratch resistance and color retention compared to anodizing, making them the preferred choice for many applications.

Cerakote vs. Powder Coating: Which is Superior?

Powder coating is another popular finishing technique that involves applying a dry powder to a substrate, which is then cured to form a protective layer. While both Cerakote and powder coating offer excellent durability and corrosion resistance, Cerakote coatings provide greater flexibility and chemical resistance. Additionally, Cerakote’s ability to bond at the molecular level results in a more uniform and durable finish compared to powder coating.

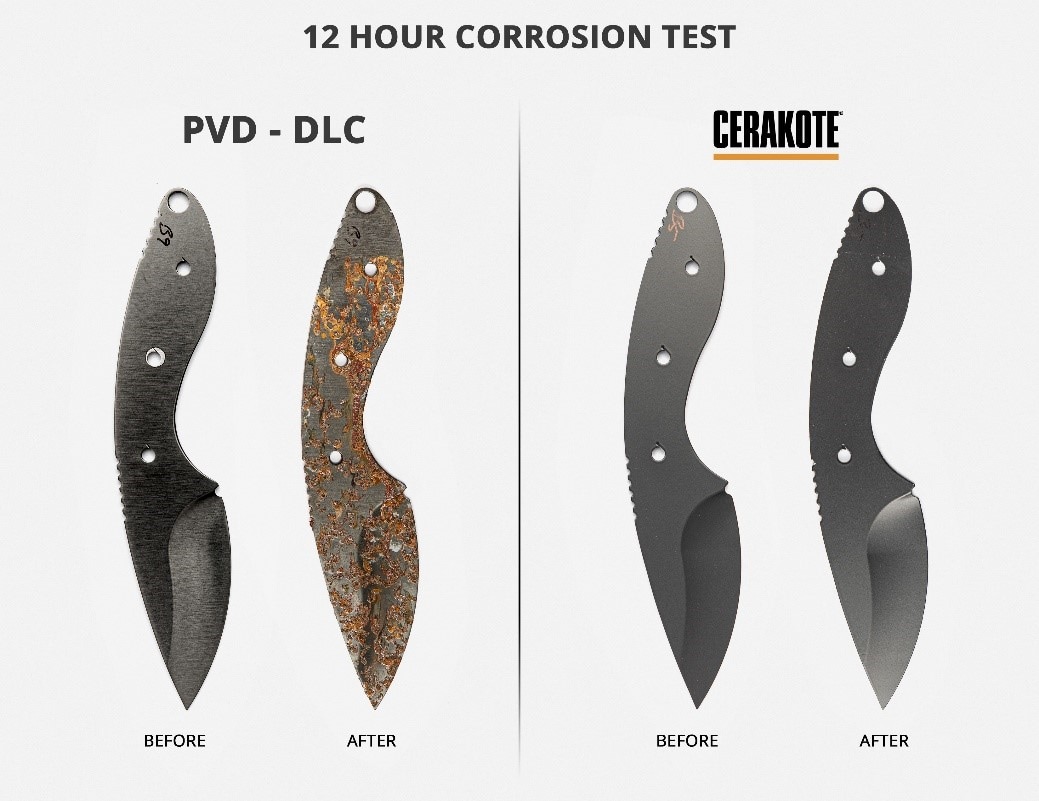

Cerakote vs. PVD Coating: Understanding the Differences

Physical Vapor Deposition (PVD) coating is a vacuum deposition process used to produce thin, durable coatings with high wear resistance. While PVD coatings offer excellent hardness and adhesion, they are typically limited to metallic substrates and have limited color options. In contrast, Cerakote coatings can be applied to a wide range of materials and offer virtually unlimited color and design possibilities, making them a more versatile choice for many applications.

Cost Considerations

Initial Investment: Balancing Quality and Budget

When considering the cost of Cerakote coatings, it’s essential to weigh the initial investment against the long-term benefits. While Cerakote coatings may have a higher upfront cost compared to traditional coatings, they offer superior durability and performance, resulting in potential cost savings over time due to reduced maintenance and replacement costs.

Long-Term Savings: Factoring in Durability and Maintenance

In addition to the initial investment, it’s important to consider the long-term savings associated with Cerakote coatings. By prolonging the lifespan of gear and reducing the need for frequent repairs or replacements, Cerakote coatings can ultimately save money and resources in the long run. Additionally, the enhanced performance and aesthetics provided by the advantages of Cerakote coatings may offer intangible benefits that contribute to overall value.

Conclusion

In conclusion, there is a myriad of advantages of Cerakote coatings that make them an ideal choice for protecting and enhancing gear across various industries. From unparalleled durability and versatility to customizable colors and designs, Cerakote provides a solution that meets the diverse needs of consumers and professionals alike. By understanding the unique properties and applications of Cerakote coatings, individuals can arm their gear with the ultimate protection and performance, ensuring that it withstands the test of time and maintains its aesthetic appeal for years to come.